Carbon Capture and Storage (CCS) involves capturing the CO2 emitted by large plants and storing it permanently underground.

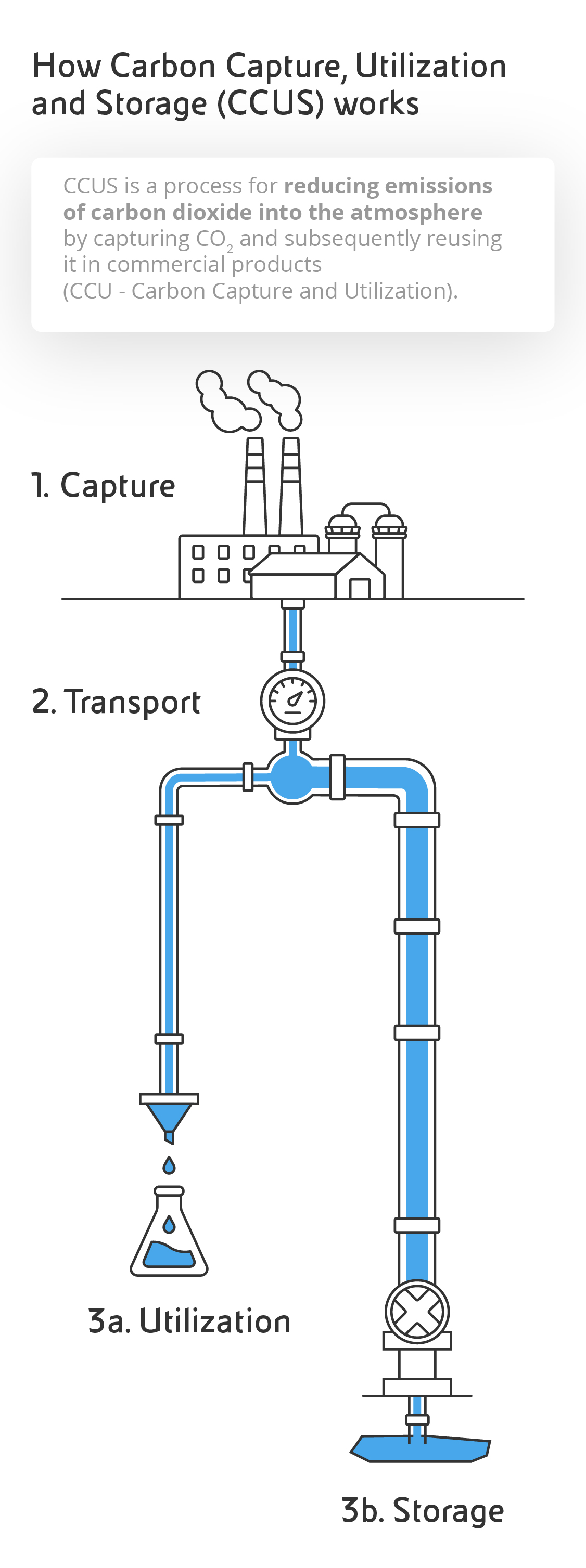

Carbon dioxide can be captured directly from industrial chimneys and either reused in subsequent production processes or permanently stored deep underground to prevent its release into the atmosphere. This suite of techniques is known as Carbon Capture Utilization and Storage (CCUS), an acronym which includes both Carbon Capture and Utilization (CCU) and Carbon Capture and Storage (CCS). In addition to supporting decarbonization, both these strategies offer the advantage of turning the climate change challenge into an economic asset, potentially opening up new avenues for growth and job creation. They are particularly useful for the “hard-to-abate” sectors, i.e. energy-intensive industries where, due to their high energy demand and specific operating characteristics, there are currently no viable technological alternatives that can reduce emissions in an efficient and cost-effective way.

The first CCS plants have been in operation since the 1970s, and new projects are expected to start around the world in the coming years.

Terrell, Texas first CCS facility in the world

Sleipner, Norway first CCS project for emission reduction only

industrial-scale CCS projects currently in operation

new capture and/or storage projects being developed

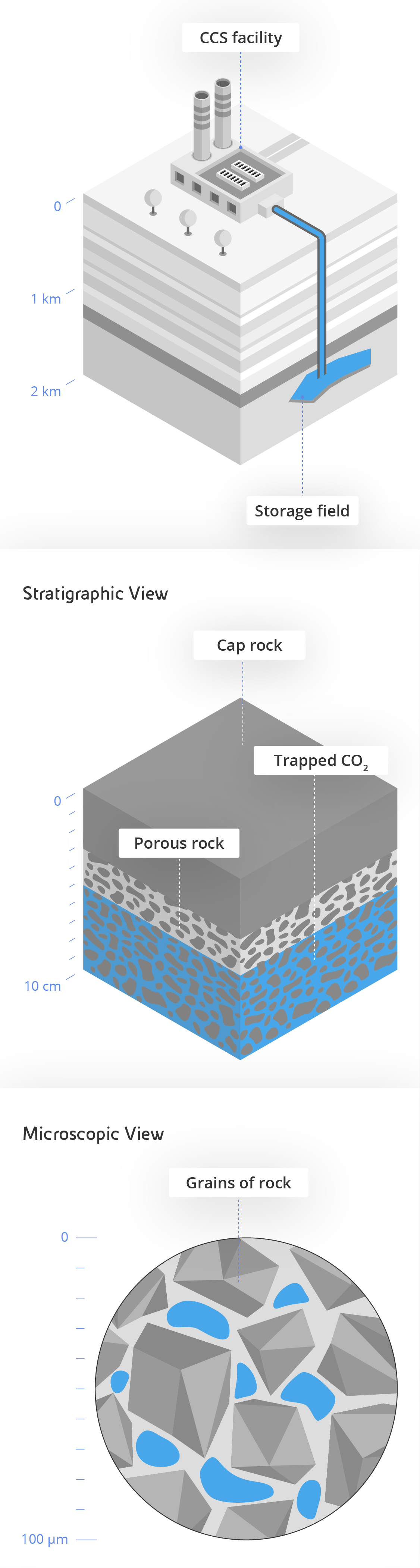

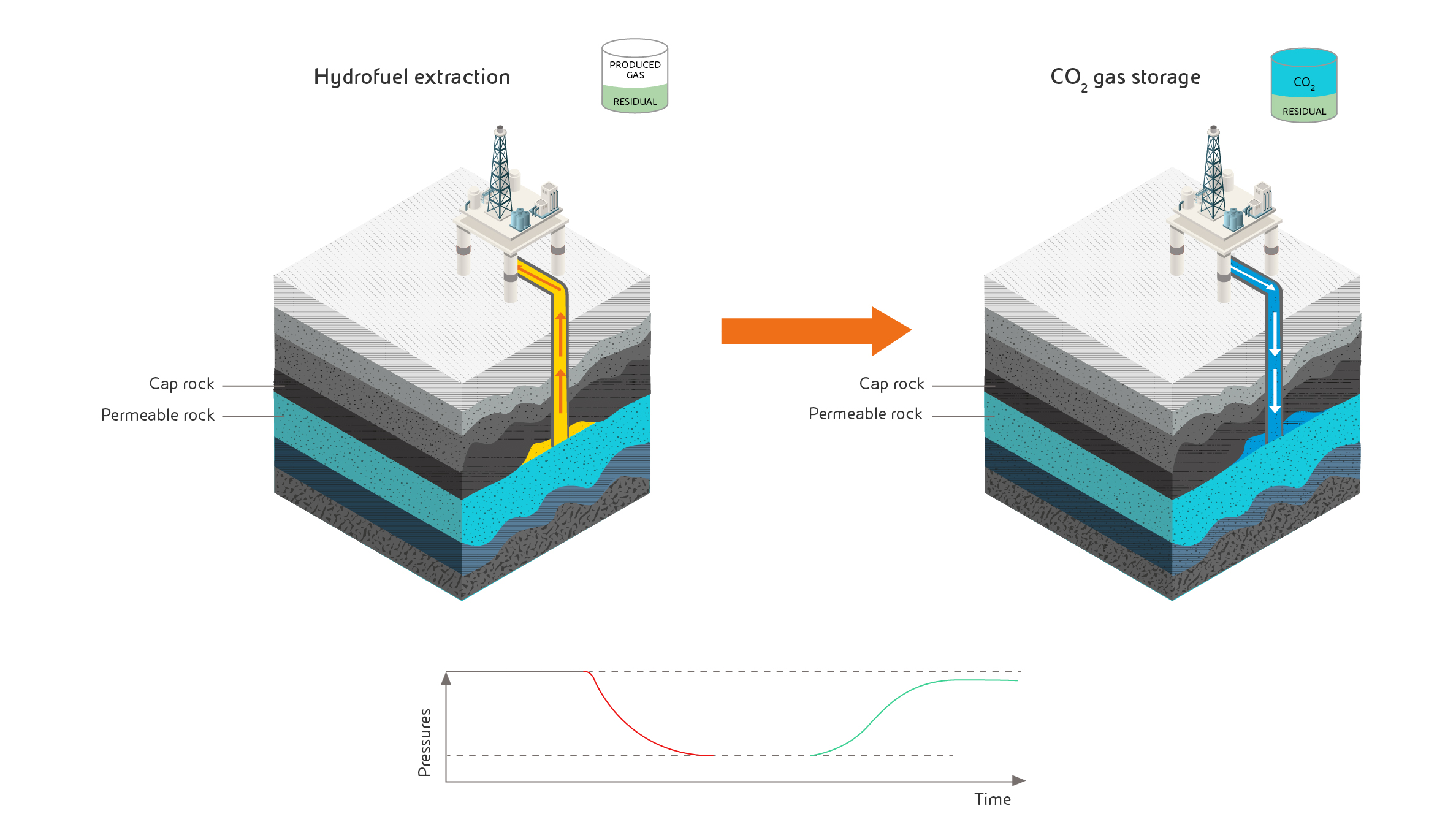

Both carbon capture and utilization (CCU) and carbon capture and storage (CCS) start with a capture stage where carbon dioxide is extracted directly from the chimneys of large industrial plants and isolated from other gases it is mixed with. Once captured, the CO2 is compressed to facilitate transport, typically by pipeline, or alternatively by sea or road. At this point we have purified, concentrated carbon dioxide, which can be reused other industrial processes as “raw material” or permanently stored deep underground. The former process is known as CCU and the latter as CCS. One application of CCU is the mineralisation of CO2 with natural mineral phases, with the resulting compounds used in cement production. CCS, on the other hand, involves injecting CO2 into deep geological formations, such as depleted hydrocarbon fields or saline aquifers, selected after detailed geological and technical assessments. Using these depleted fields offers significant advantages, as it allows us to use well-known geological structures, allowing accurate predictions to be made about the distribution of CO2 within them. In addition, reusing existing infrastructure makes it possible to create fast-track, low-cost projects, applying circular economy principles to decarbonization. The methodologies underpinning CCS are reliable and mature, based on lessons learned from underground natural gas storage - a technique Italy has been using for its strategic reserves since 1964, in compliance with the highest safety standards.

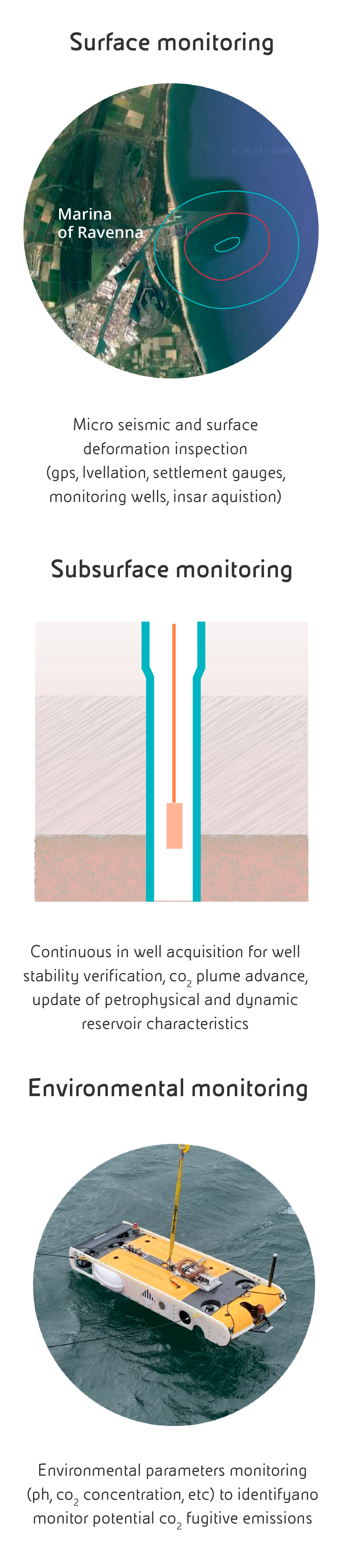

CCS projects are based on proven, reliable technologies, drawing on Italy's extensive experience in underground natural gas storage - a field in which Italy has been a pioneer since the 1960s. Every operation in the Ravenna CCS project will benefit from a comprehensive monitoring framework already in place in Ravenna, which has previously been used for extraction operations.

Reuse of depleted fields

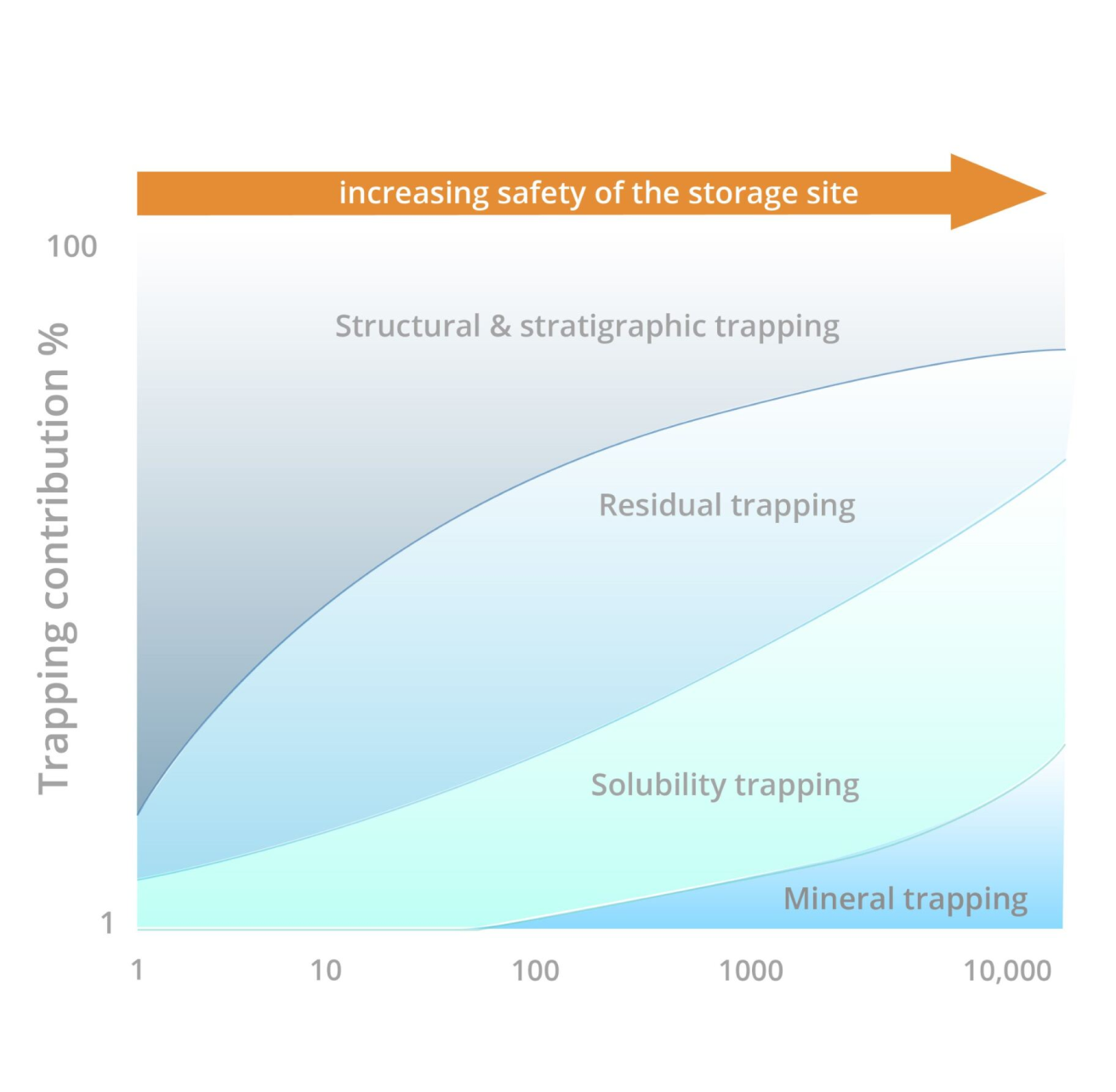

In CCS plants, carbon dioxide extracted from industrial chimneys is compressed and injected into deep geological formations suitable for its storage, where it is trapped underground indefinitely.

Our experience in gas

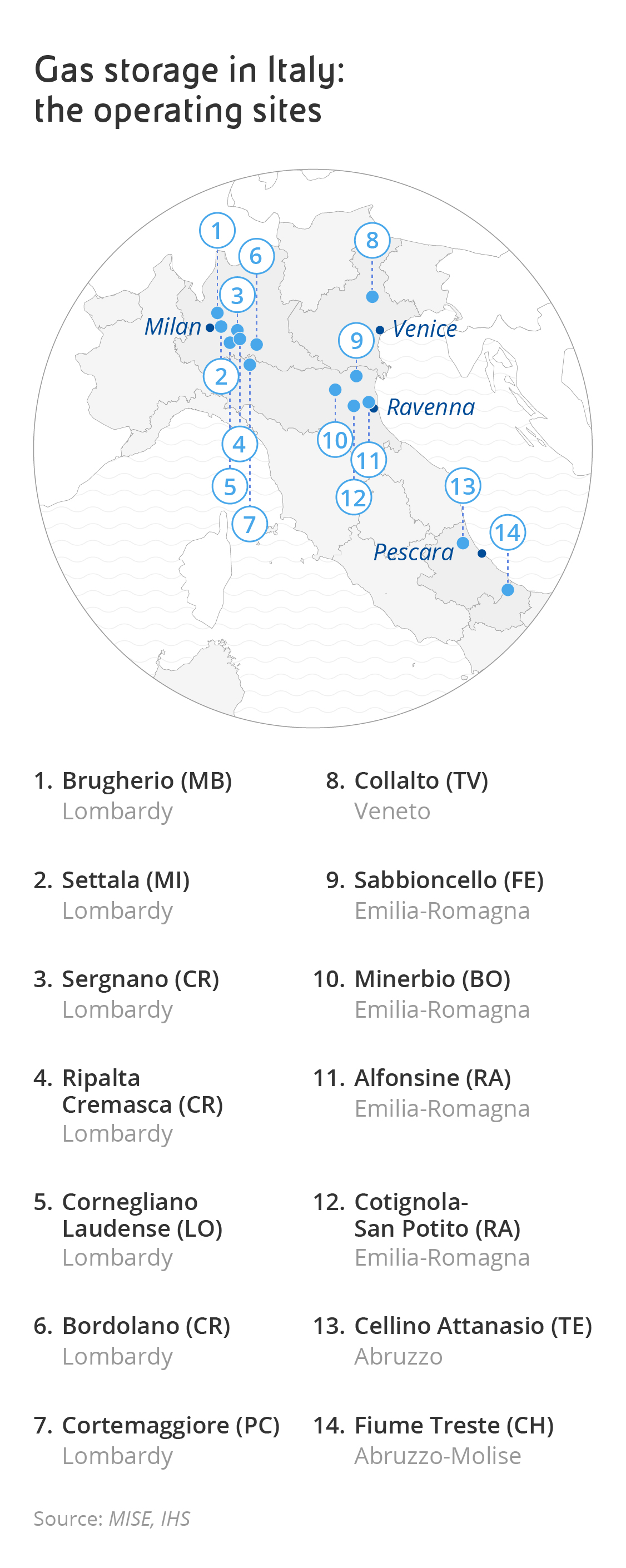

The process of capturing and storing carbon dioxide is safe and technically mature. It uses proven, commercially available capture technologies and draws on the expertise gained from over a century of natural gas storage. Since the 1960s, Italy has been using depleted gas fields to store strategic gas reserves. It has 10 active sites with a working capacity of over 14 billion m³ and there haven't been any major incidents (source: Italian Ministry of Economic Development). Globally, CCS initiatives have been in operation for years, for instance Snohvit (since 2008) and Sleipner (since 1996) in Norway, and no CO2 leakage has been reported.

CCS builds on its long experience in the underground storage of natural gas, a sector in which Italy has been operating since the 1960s.

in natural gas storage in Italy

natural gas storage in Italy since the 1960s

natural gas stored in underground sites in Italy

depth of reservoirs under the Adriatic seabed

Eni and Snam are developing a carbon capture and storage (CCS) project to reduce emissions from “hard to abate” industrial facilities.

Eni and Snam are developing a carbon capture and storage (CCS) project to reduce emissions from “hard to abate” industrial facilities.